Our onboard bioreactors explained

Another innovation in sustainable rail travel

All toilets on our WESTbahn trains are equipped with a bioreactor. Specifically designed for use in rail transport, our onboard bioreactors are comparable to high-performance mini wastewater treatment plants.

Our bioreactor explained

On this page we have summarised all information about our onboard bioreactors.

How does the bioreactor work?

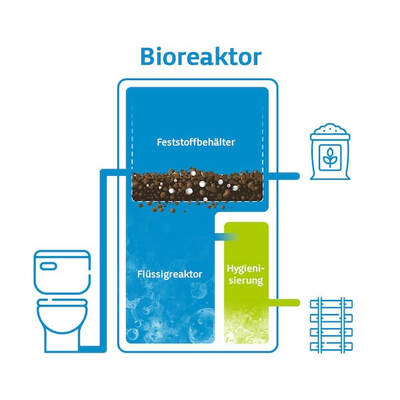

The system operates in several stages: Initially, solids are separated and biologically degraded in the solid reactor to reduce their volume. In the liquid reactor, the wastewater undergoes biological treatment and purification. Finally, the purified liquid is hygienized physically and thermally before being automatically discharged onto the trackbed during train operation.

The bioreactor represents an innovative solution for sanitary wastewater treatment in trains. Unlike conventional systems that require regular emptying, the bioreactor can operate continuously for up to 6 months without interruption.

Another step towards sustainable rail travel

The treatment process is purely biological and chemical-free, and the purified water complies with European TSI LOC&PAS guidelines. Residues are safely disposed of through the sewage system during the regular service intervals.

The bioreactor provides an advanced and efficient solution for cleaning sanitary wastewater in trains, offering both ecological and economic benefits. Its operation is safe and reliable, with constant water quality, fully automated operation, and integrated diagnostics. It contributes to improved hygiene in disposal and minimizes odor-causing substances as well as the risk of flammable or explosive gases.

If you have questions, contact us by e-mail at meinenachricht@westbahn.at or phone from Mon - Fri from 8:00 to 18:00 and Sat, Sun or public holidays from 9:00 to 15:00 on +43 1 899 00.